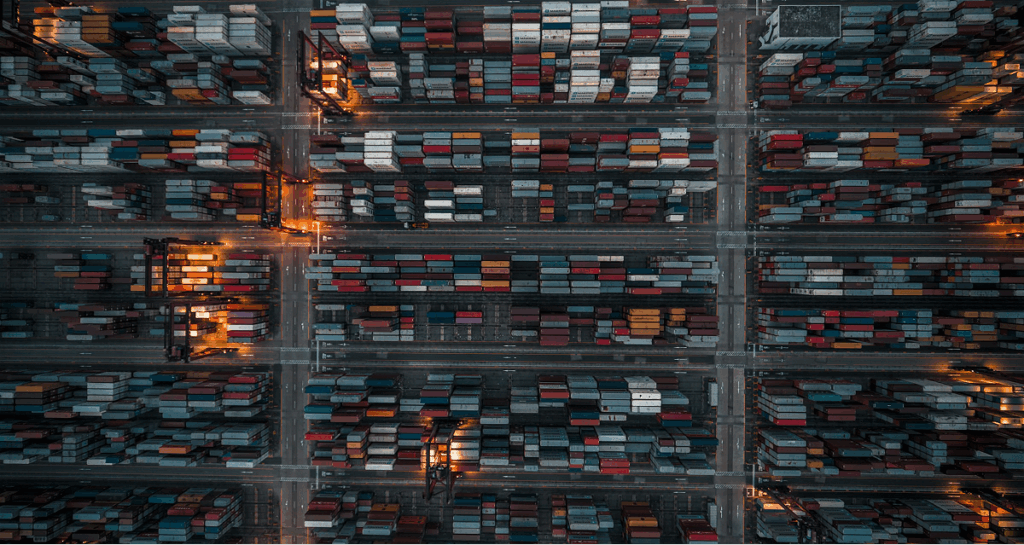

Global supply chains remain in constant turmoil with many organisations facing unprecedented levels of disruption to their business operations. Not helped by a depressing economic climate, which shows few signs of improving, consumer confidence is staying steadfastly low.

At the same time, the global trade conflict continues to deepen. After weeks of consultation, EU member states approved their own tariffs on a wide range of US products in retaliation against 25% tariffs imposed by the US on imports of steel and aluminium from the bloc. This came on the same day that the US announced a 90 day pause on higher tariffs for most countries, except China. A planned trade deal between the UK and US may provide some relief in the UK, but for how long? Whether future announcements are detrimental or positive, continued market chaos is likely to continue for the UK.

Add in, increased costs, labour shortages, rising geopolitical tensions, cybersecurity attacks, and weather-related disasters costing 27 billion in damages in the US alone, and it’s clear that a state of perpetual instability is becoming the norm for today’s supply chains.

Senior executives agree, with 84% saying, in a recent survey, that they have encountered disruptions within their supply chain over the past year. It underscores the need to be prepared for the unexpected, understand the potential consequences, and have a plan in place to mitigate such risks.

But how can organisations go about creating a strategy for events that are, by their nature, unpredictable? The answer is by building a comprehensive plan that brings together the capabilities, processes and technologies needed to continue operating efficiently, come what may.

Inclusive, end-to-end supply chain planning

The first step is to create an overarching strategy that encompasses the entire supply chain. Having visibility across all areas will support synchronised planning and communication across disparate functions.

By bringing together teams and processes, organisations can start to overcome the traditionally fragmented approach to supply chain management. Uncoordinated procedures inevitably create an inefficient and weaker supply chain, which makes it particularly vulnerable to disruptions.

Whereas, resilience is strengthened by collaboration between functions, if backed with integrated data systems and communication methods to enable sharing of real-time information. Keeping all parties in the loop, with relevant data and meaningful insights, encourages better and faster responses to problems, as well as increases awareness of potential forthcoming issues.

Ideally, what’s needed is an end-to-end connected platform where all departments, offices and sites are working from the same consistent, up-to-date data. And, are not required to change systems to find or cross-check relevant information and iron out anomalies.

Incorporate AI and automation

Next, it’s vital to incorporate intelligent automation to improve and speed up decision making. Companies are already using data tools to forecast supply and demand planning, but they now have the opportunity to incorporate AI’s ‘always-on’ capabilities to dynamically evaluate and adapt to changes in supply and demand.

AI-powered solutions can assess how work is progressing by automating data gathering for analysis and optimisation. Automation can handle routine issues, leaving supply chain professionals free to focus on more strategic tasks. Furthermore, AI can facilitate transparent, trackable decision-making to accommodate predicted supply chain disruptions or react to unexpected ones. This level of auditing provides vital insights that will help refine future decisions and actions for the next time similar circumstances materialise, improving outcomes in the long-term.

It’s critical to have a technology platform that’s designed for scalability and extensibility to manage changing workloads and requirements

Additionally, organisations can leverage AI to predict the likelihood of disruptive events happening. Knowing how often they occur and how they have unfolded in the past can inform decision-making and planning. Whether that’s examining competitor behaviour or economic trends, AI tools can process millions of pieces of real-world data to model likely what-if and worst-case scenarios that could impact the supply chain. While these instances may seldom occur, proactive scenario pre-planning provides the foundation for an effective response in the event of real-world disruptions or disasters.

Organisations should identify the specific issues which present the highest risk to their business and ensure appropriate mitigation measures are ready to be activated immediately they are needed.

Invest in agile, scalable technology

Restrictive working practices coupled with outdated technology can make it harder to react effectively when disruptions occur. Building long-term supply chain resilience means finding a best-in-class solution and partner with deep domain expertise to guide deployment of appropriate modern technologies.

When considering options, businesses should keep in mind fundamental requirements for flexible, agile solutions. These include checking how a software or platform supports data integration and cross-organisational collaboration, whether it can simulate market conditions in near real-time, if the technology architecture is compatible with AI, and how easily does it scale.

It’s critical to have a technology platform that’s designed for scalability and extensibility to manage changing workloads and requirements. Therefore, organisations should look for products with a cloud-native architecture for scalability and resilience, a microservices-based approach for flexibility, and solutions that are easy to configure and maintain without specialised IT expertise.

In an unstable commercial world, it’s essential for entities to build resiliency into their end-to-end supply chain and have the right technical infrastructure to do this. What’s more, investing in modern technologies and platforms can bring other benefits too. Modern solutions that respond easily to changing conditions, remove manual processes, and leverage the powerful potential of AI can also deliver competitive advantage. For example, utilising AI’s power for data crunching and analysis can uncover hidden opportunities that arise out of unexpected events but may have gone unnoticed in the past.

By making well-informed technology choices, organisations can build more resilient supply chains not just to survive in today’s unstable conditions, but also to optimise performance and operate more profitably.

Simon Bowes

Simon Bowes is CVP Manufacturing Industry Strategy EMEA at Blue Yonder. An engineer by background, he brings 25 years of experience shaping manufacturing strategy, innovation, and R&D across EMEA.